TM 11-5855-217-12

38-750

3-8

5-9.

I

WARNING

Wear a face mask and asbestos gloves

Remove rust and corrosion from metal surfaces

when working in the vicinity of the

by sanding them lightly with fine sandpaper.

xenon lamp.

Brush two thin coats of paint on the bare metal

to protect it from further corrosion. Refer to ap-

b. Clean both sides of the window using soap

plicable cleaning and refinishing practices and

and water. Rinse away soap and dry the window

materials specified in SB 11-573 and TB 746-10.

with a clean, lint free cloth.

c. Clean the reflector using a clean, lint free

cloth dampened with alcohol. Gently wipe from

center to outer edge. Do not use any cleaning

o r g a n i z a t i o n a l maintenance personnel are re-

solvents or abrasive compounds on the reflector.

sponsible for cleaning the reflector.

Section III. ORGANIZATIONAL TROUBLESHOOTING AND REPAIRS

trouble symptom is not listed, refer to higher

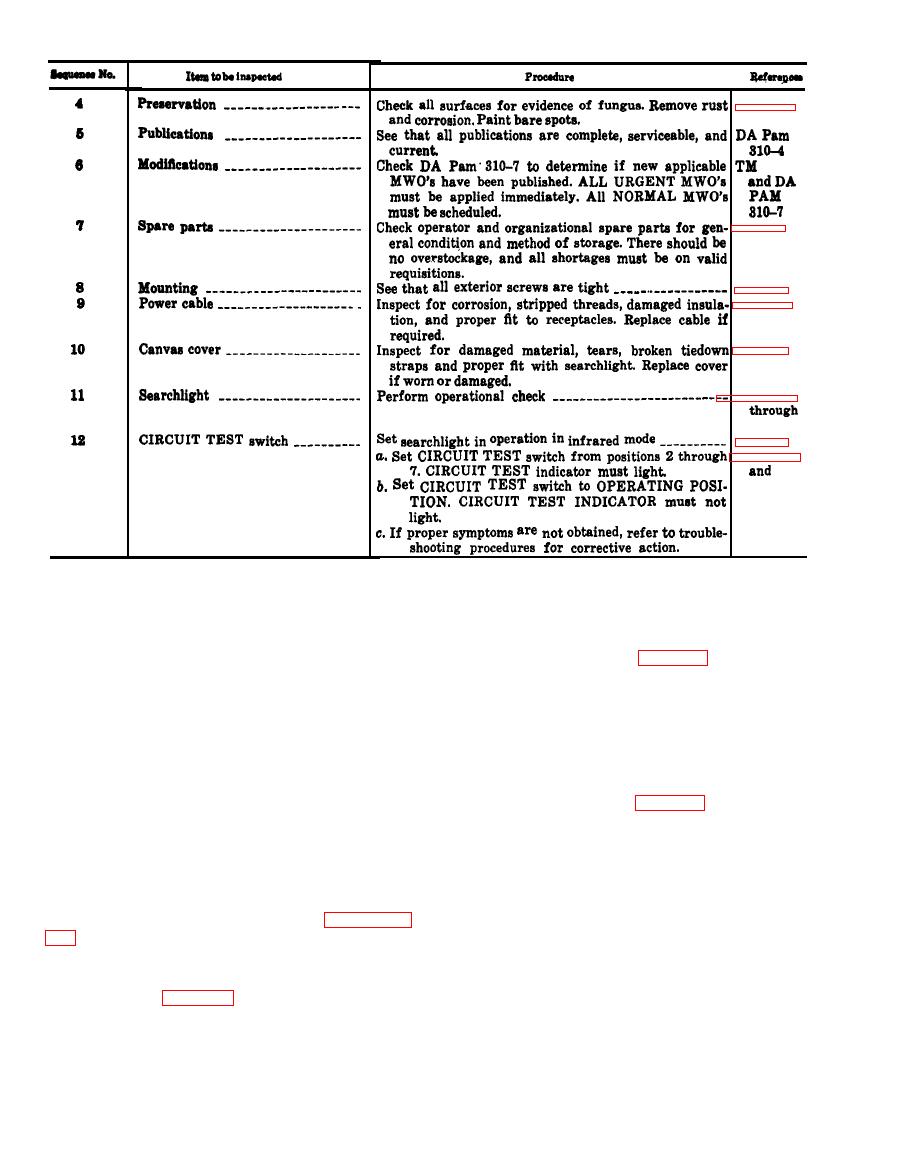

5-8. General

category of maintenance. After performing each

Troubleshooting of this equipment is based on

corrective action sequence, return to the starting

the operational checks described in paragraph

procedure to check whether the trouble symptom

is still present. If the symptom is still present, re-

ment, follow the operational checks until a trouble

fer to higher category of maintenance.

symptom is found, and then refer to the trouble-

NOTE

shooting chart (para 5-9). Locate the trouble

Check to be sure that the CIRCUIT

symptom in the chart, isolate the trouble using

TEST indicator lamp is not defective be-

the CIRCUIT TEST switch and indicator, and

fore starting the troubleshooting pro-

cedures.

perform the indicated corrective action. If the