TM 11 5855-250-12&P

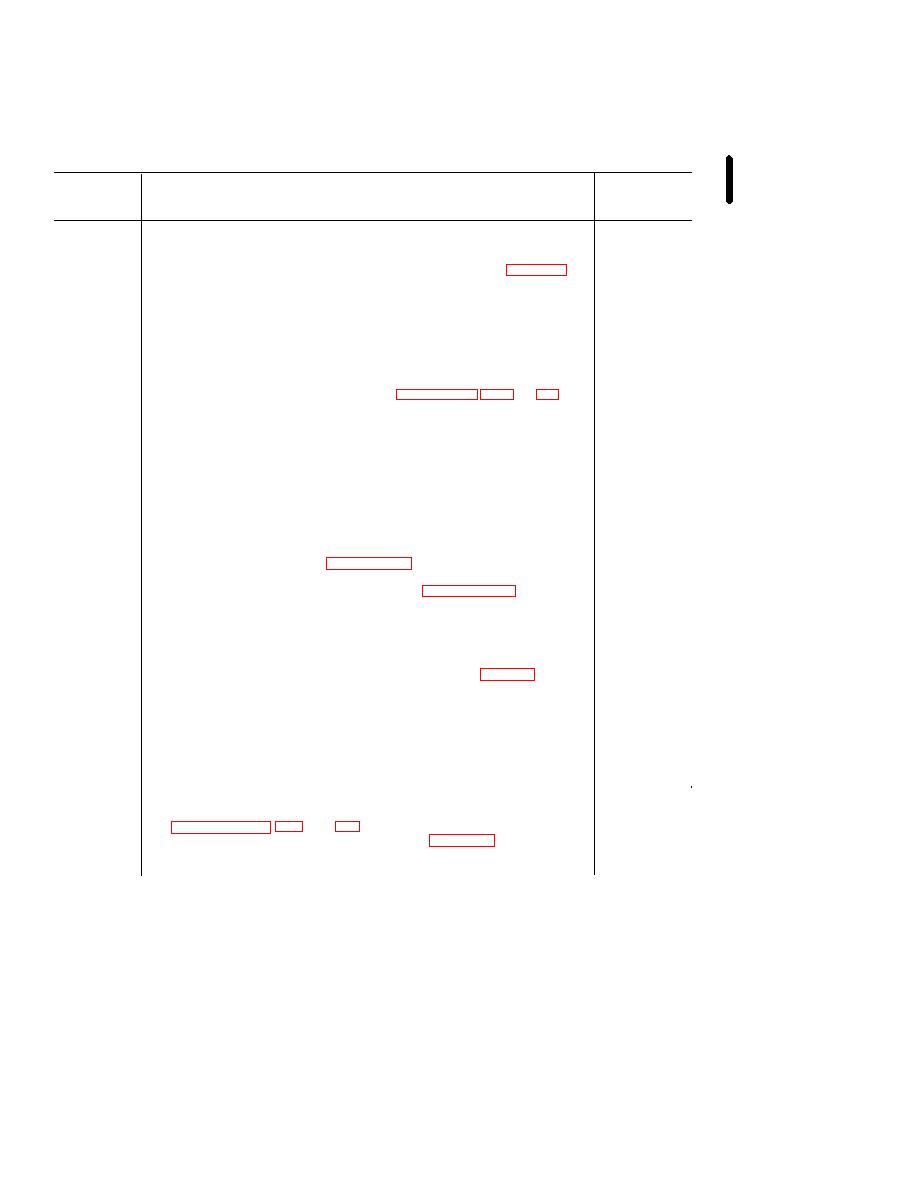

Table 4-2. Organizational Preventive Maintenance

.Monthly Checks and Services

Total task-hours required: 1.5

Sequence No.

Item to be inspected procedure

Work

.

Time

(M/H)

1

COVER ASSEMBLY

0.1

Inspect for tears, damaged buckles, dirt, and proper fit with cowling assembly.

Clean if needed. Replace if worn or damaged. Refer to figure 1-3 for

location.

2

SEARCHLIGHT HOUSING ASSEMBLY

0.1

Clean exterior surface including nameplates; make sure that nameplates are

legible. Inspect cowling latches; check to see that they close properly.

Inspect blower inlet and outlet screens; remove any obstructions. Inspect

heat exchanger assembly air ducts for accumulations of dirt. If needed,

remove blower outlet and inlet screens; set main power switch to OFF,

and flush out air ducts by pouring water into blower inlet port. Replace

blower inlet and outlet screens. Refer to paragraph 3-3, 3-8b, and 4-7 for

detailed procedures.

NOTE

Heat exchanger assembly is sealed to prevent water from entering

searchlight housing assembly.

3

COWLING ASSEMBLY

0.1

Remove and check inner gasket and outer ring; they must make a secure and

watertight seal. Clean glass if needed. Replace cowling assembly and

check to see that it fits properly with searchlight housing assembly. Inspect

cowling latches; check to see that they close properly. Replace cowling

assembly if it is damaged, not watertight, or fits improperly to searchlight

housing assembly. Refer to paragraph 3-8b for detailed procedures.

4

INDICATOR LIGHT

0.1

Inspect for dirt; clean if needed. Refer to paragraph 4-6 for detailed

procedures

5

PRIMARY REFLECTOR

0.1

Inspect for scratches or pitted surface. Clean with pure alcohol; use lens

tissue or lint-free cloth.

6

LAMP HOUSING ASSEMBLY

0.1

Inspect for cracked or broken lens, and corrosion. Refer to figure 1-5 for parts

location.

7

CABLE ASSEMBLIES (WHERE APPLICABLE)

0.1

Inspect for corrosion, stripped threads, damaged insulation, broken strands,

and proper fit to receptacles; replace if needed.

8

SEARCHLIGHT

0.3

Perform an operational check by following start, standby, and stop

procedures. Place searchlight of all modes of operation and check for

proper response. Inspect indicator light on control box for proper operation

during overdrive mode. If lamp is defective, remove lens cap; turn it

counterclockwise and replace lamp.

Replace lens cap.

Refer to

procedures. Check for completeness. Refer to appendix B for list.

9

MT-3900A/GSS-14(V)

0.1

Turn azimuth and elevation handwheels; see that mechanical action

Change 1 4-3